Plastic Injection

Lacus Innovations is your trusted ally for the creation of custom plastic parts. Thanks to our advanced equipment, we offer a variety of solutions to meet your specific requirements, whatever your sector of activity.

At Lacus Innovations, we value our expertise, our quality of service and our commitment to innovation. We’re here to turn your ideas into reality, so don’t hesitate to contact us to discuss your custom plastic molding projects.

1. Diversity of plastics

The variety of plastic materials offers a world of opportunities for innovation and development. At Lacus Innovations, we use this diversity to design and manufacture customized parts to meet your needs, in all sectors of activity.

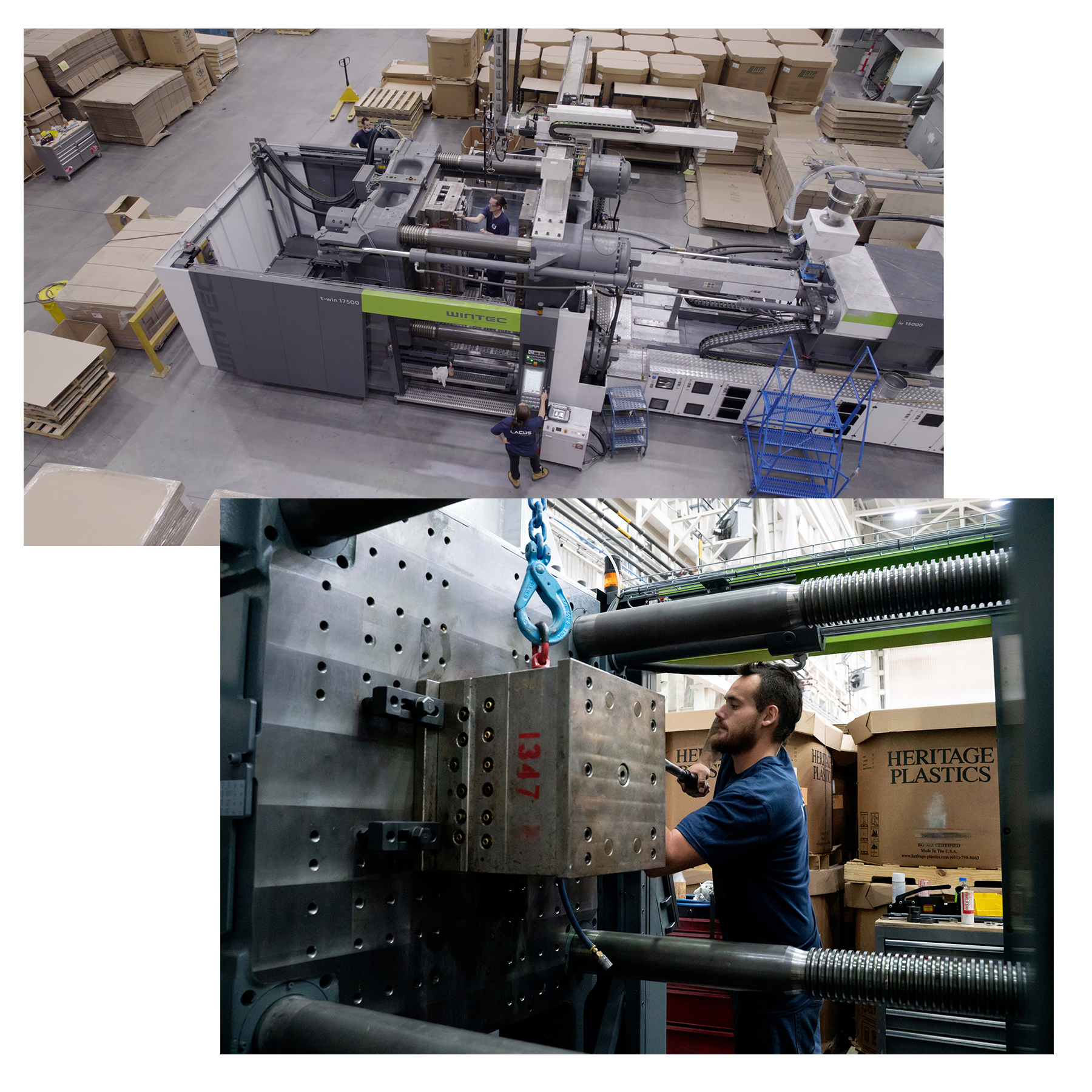

2. Injection molding - expertise and versatility

With our expertise in injection molding, we shape parts of various weights, all tailor-made to meet your needs. Our diversified machine park allows us to produce both small and large series of parts.

3. Turnkey service for your projects

At Lacus, we offer a turnkey service for the development and production of plastic parts. From initial design to mold making and custom part production, we cover every step of the process.

4. Rigor, creativity and quality control

At Lacus, we offer a turnkey service for the development and production of plastic parts. From initial design to mold making and custom part production, we cover every step of the process.

5. Assembly to your specifications

We are ready to meet all your assembly requirements. Whether you need components delivered individually, as a subassemblies, or as complete assemblies, we can satisfy your demands.

6. Mould maintenance and storage

Rigorous maintenance of our molds is a priority. We inspect each mold before production and apply a maintenance program after each production to ensure consistent performance.

7. Advanced technology

Our machine park is equipped with 10 injection molding machines that perfectly meet the challenges of a fast-changing market. Our plastic injection presses range from 35 tons to 1750 tons of clamping force, and operate 24/7 to mold a variety of plastic products.

8. Responsible recycling

We value sustainability by recycling rejected parts back into our processes. Thanks to specialized granulators, we recycle 100% of our rejects, helping to preserve the environment.